Robert C. Turner

RBP, FBPA

Figure 1. Arthur J. Olson, Ph.D., Professor / Director, Molecular Graphics Laboratory, Molecular Biology Department, The Scripps Research Institute, La Jolla, California,shown seated in front of a Z Corporation stereolithography printer, and samples of 3-D molecular models that were created in his laboratory. [Photo credit: Alan McPhee]

Figure 2. The wood-like model (left) depicts the molecular surface of the beta-lactamase enzyme. This enzyme can confer drug resistance to some bacteria. This model was made on the Helisys rapid prototype machine -- built up by laminating layers of paper, which have been cut with a laser. The amber-plastic model (right) depicts an assembly of pilin protein subunits. These subunits assemble to form long projections that stick out of bacterial cells, that can attach to other cells (and infect). This model was made on a 3D Systems Stereolithograpy rapid prototype machine -- built up by photo polymerizing a resin with a laser, layer-by-layer.

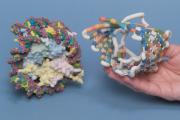

Figure 3. Both models were made on a Z Corporation 406 color printer (materials: gypsum, color binder, superglue) built up by ink-jet printing successive layers of gypsum powder with the color binder. The surface model (left) depicts the nucleosome core particle -- consisting of eight histone proteins and a DNA double helix wrapped twice around the proteins. The nucleosome forms the basic packaging unit of DNA in the chromosome. The tube model (right) depicts the porin protein -- a beta-sheet structure that imbeds in cell membranes to form channels. Color coding along the folded chain represents the sequence of amino acids.

Stereolithography (STL) is a relatively new technology that enables fabrication of 3-D prototype models. More than two dozen years ago the technology evolved from the need in the manufacturing industry to pre-visualize objects before they were mass produced. Prior to STL, prototype models could only be made through very time consuming methods which included manually cutting plastic, carving wood, and shaping clay. Later, computers with computer-aided-design (CAD) and computer-aided-modeling (CAM) software were capable of creating 3-D images. Finally, the CAD/CAM technologies were harnessed to drive devices called "printers" that made 3-D models from a variety of materials. This technique is generally referred to as rapid prototyping (RP). The ability to create a tangible 3-D object had wide appeal for a variety of applications including molecular biologists studying complex individual molecules and intricately detailed molecular structures (Figure 1).

The initial printers, resembling office copy machines, made models from paper and various plastic materials. Models made of paper were constructed from printers that laid down hundreds of very thin layers of fused paper and glue. The plastic models were virtually carved by lasers from blocks of plastic or from layers of molten polymers. Although all of these various RP techniques created solid 3-D models, the paper and plastic type materials were somewhat limited in delineating fine details and could only be produced in one color (Figure 2).

In recent years, however, significant printer advancements have been made by using extremely fine powdered materials to build the models. Using materials such as cornstarch or gypsum now enables STL printers to function much the same as a color laser copier (CLC). With CLC technology, subtractive color toners (cyan, magenta, and yellow), plus black, are dispersed across paper in four respective passes and fused to create a completed image (2-D). Similarly, STL printers distribute, via inkjets, very thin layers of predetermined amounts of powder, colored dyes, and glue. Each layer builds upon the previous layer until the model is built. The model is slowly built over a number of hours and the current practical size limitation is about one cubic foot (~ 0.305 cubic meter). Final retouching and/or resin coating may also be needed to complete the process (Figure 3).

In addition to assisting molecular biologists in the study of molecules,

STL is being utilized for a variety of other applications in the medical

and scientific arena. Some applications that have already proven successful

include: surgical implants, prosthetic devices, cardiac replacement valves,

and artificial heart pumps. Further developments of STL technology will

eventually allow larger models to be built and at faster speeds. STL offers

the biomedical communications milieu a very dynamic resource to provide

3-D models. The models help visualize data and communicate valuable new

information, information that is only made possible through the ability

to create the third dimension.

Suggested Reading:

Brain, M. How stereolithography (3-D layering) works, How stuff works,

http://computer.howstuffworks.com

Caffey, T., Interview with Chuck Hull, Inventor of stereolithography

and founder of 3D Systems, Rapid Prototyping Network,

http://www.rapidprototyping.net

Harrysson, O., Cormier, D., Rudd, L. Biomodels: rapid prototyping finds

"new" surgical applications, Rapid Prototyping Network,

http://www.rapidprototyping.net 7/25/2002

Neckers, D. Stereolithography: An introduction CHEMTECK 1990, 20, p. 615-619

Priluck, E. Separation of conjoined twins planned using BioMedical Modeling

biomodels and Object Geometries RP Systems, Rapid Prototyping Network,

http://www.rapidprototyping.net 8/31/2002

Skawinski, W., Busanic, T., Ofsievich, A., Venanzi, T., Luzhkov, V., Venanzi, C. The application of stereolithography to the fabrication of accurate molecular models Journal of Molecular Graphics and Modeling 1995, 13, 126-135

Yourtee, D., Emery, J., Smith, R., Hodgson, B. Stereolithographic models

of polymers Journal of Molecular Graphics and Modeling 2000, 18,

p. 26-28

Robert C. Turner is Director of the BioMedical Graphics Department, The Scripps Research Institute, La Jolla, California. He is a Registered Biological Photographer, holds an MBA degree in Health Care Administration, is a Fellow of the BioCommunications Association (BCA), and is a Past President of BCA.

(All models illustrated in this article were created under the direction

of Dr. Olson.)

http://www.scripps.edu/pub/olson-web/